Autonomous Blast Hole Inspection

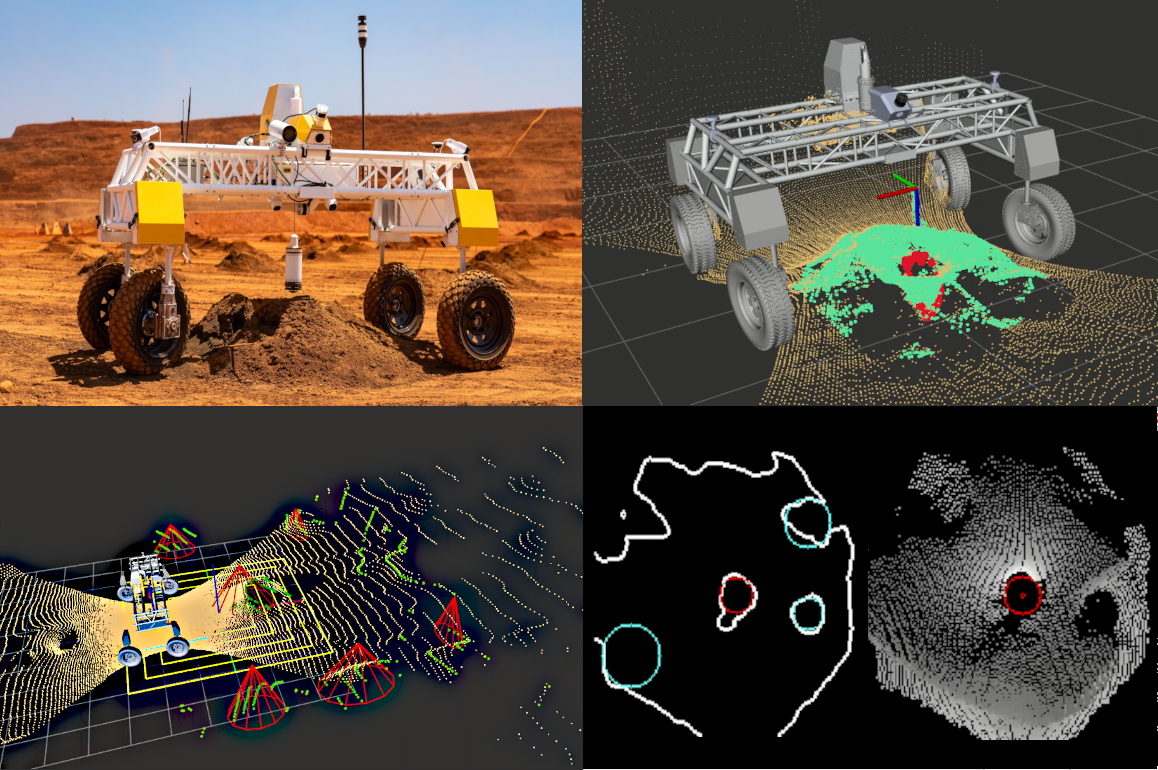

Developing precision guidance, navigation, and control for Rio Tinto's 'DIPPeR' (Downhole Inspection, Probing, and Perception Robot), enabling centimetre-accurate autonomous positioning for blast hole inspection in remote mining environments.

The Challenge

Mining operations require regular inspection of blast holes across vast, remote sites. These inspections involve lowering sensor equipment (sondes) into blast holes to gather geological data. Currently, this process requires human operators to manually position heavy equipment over each blast hole—a time-consuming and potentially hazardous task.

The challenge was to develop an autonomous system capable of detecting blast holes, navigating to them, and positioning a sonde deployment mechanism with centimetre-level accuracy—all while operating in the harsh conditions of an active mine site.

My Contribution

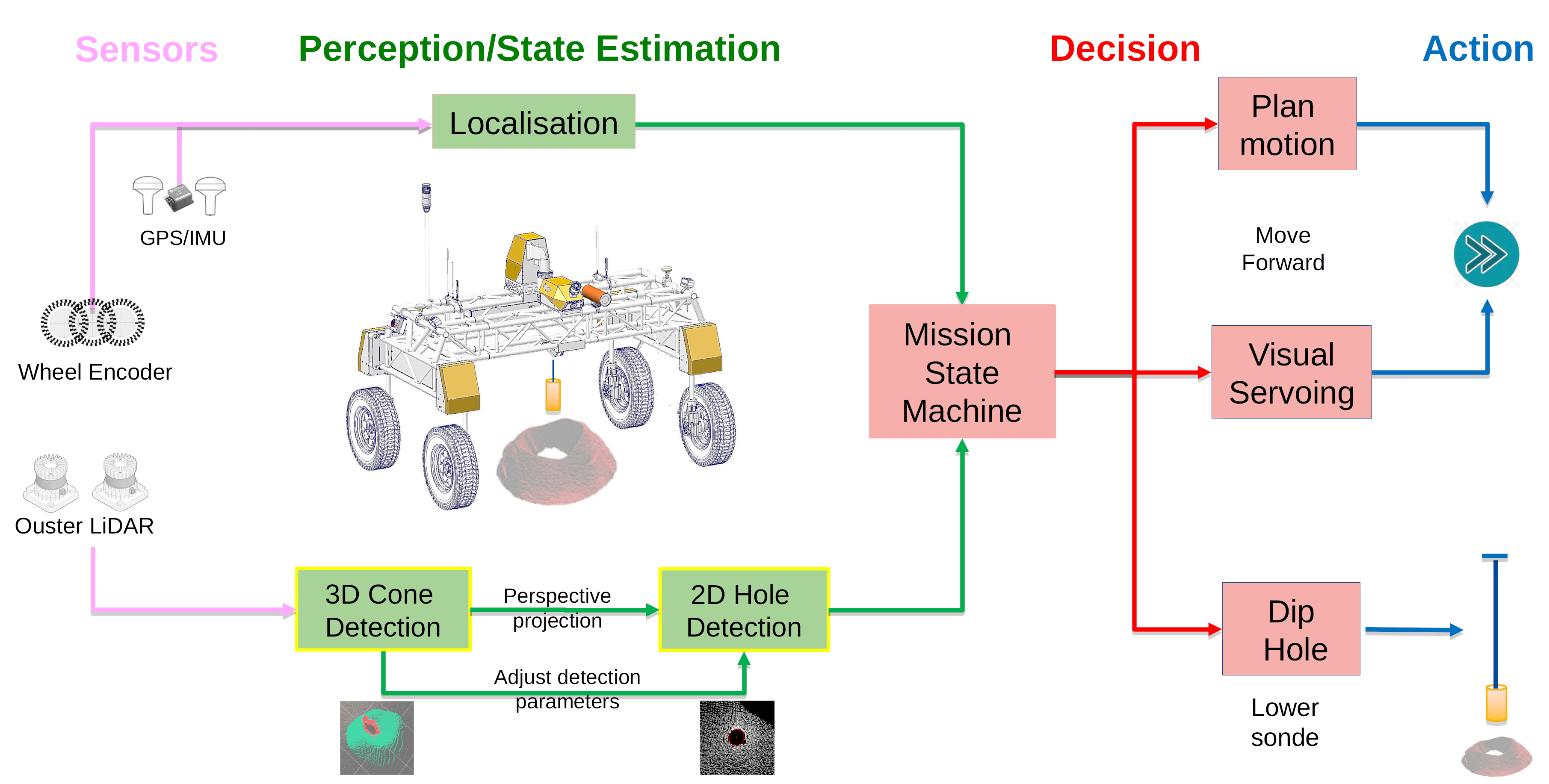

I led the development of the entire guidance, navigation, and control (GNC) system for the DIPPeR robot. Leveraging my prior experience from PhD research and agricultural robotics, I built the system from the ground up in under 12 weeks. Key contributions included:

- Localisation system — High-precision position estimation fusing GPS, IMU, and wheel odometry

- Precision positioning — Control algorithms achieving centimetre-accurate servoing over detected blast holes

- System integration — End-to-end integration with the existing DIPPeR platform and sonde deployment mechanism

Technical Approach

The GNC system operates as a proximity-based adaptive navigation system, using a four-stage state machine that dynamically switches between coordinate frames based on distance to target:

- Global navigation — Using pre-recorded GPS positions from drilling, the robot navigates to each blast hole in the UTM frame with coarse accuracy

- Fine planning — Once within ~3m and the cone is detected, the system switches to the local odometry frame for smooth trajectory planning to the target

- Fine positioning — Within ~1m, visual servoing in the robot body frame aligns the sonde precisely over the detected hole

- Dipping — Once aligned, the sonde is deployed into the blast hole for inspection

A key insight was decoupling localisation across these stages—GPS provides coarse global positioning but exhibits jumps and drift, while odometry offers smooth local estimates ideal for close-range operations. The precision positioning phase was particularly challenging, requiring careful calibration of the sensor-to-actuator chain and robust handling of terrain variations.

Results & Impact

The system was successfully demonstrated to Rio Tinto stakeholders in the Pilbara region of Western Australia. Field trials showed consistent centimetre-accurate positioning over detected blast holes across varied terrain conditions.

The success of this demonstration was instrumental in securing the project's continuation as part of a $16 million grant. The robot has since been deployed operationally on a mine site in Utah, USA, marking a significant milestone in autonomous mining inspection.

Rapid Development

One aspect I'm particularly proud of is the development timeline. By leveraging modular software architecture and extensive prior experience, I delivered a functional GNC system in just 12 weeks—from initial requirements through to successful field demonstration. This rapid delivery was critical in meeting project milestones and maintaining stakeholder confidence.