GNC for Off-Road Swerve-Steer Robots

Developing a complete guidance, navigation, and control system for omni-directional wheeled mobile robots, along with a simulation-to-deployment pipeline that enabled multiple concurrent research and industry projects.

The Challenge

When conducting research across new and varied application domains, the differing requirements can often call for development of new bespoke solutions from scratch. This creates a bottleneck that is unsustainable as the number of such projects increases; development of navigation, localisation, sensor integration, and control systems consume significant development time before the actual research can begin.

Thus, our team needed a robust, reusable GNC system that could support diverse projects and their requirements—from agricultural monitoring to mining inspection to firefighting—without requiring each researcher to become an expert in low-level robot control.

My Contribution

I led the development of the entire GNC stack for our omni-directional wheeled mobile robots. This was a ground-up effort encompassing:

- Localisation system — Fusing GPS, IMU, wheel odometry, and visual features for robust position estimation across varied terrain

- Path planning — Global and local planners suited to off-road environments with obstacles and terrain variations

- Motion control — Low-level controllers for the swerve-steer drive system, handling the unique kinematics of omni-directional locomotion

- Sensor integration — Unified interface for colour cameras, infrared cameras, LiDAR, and depth cameras

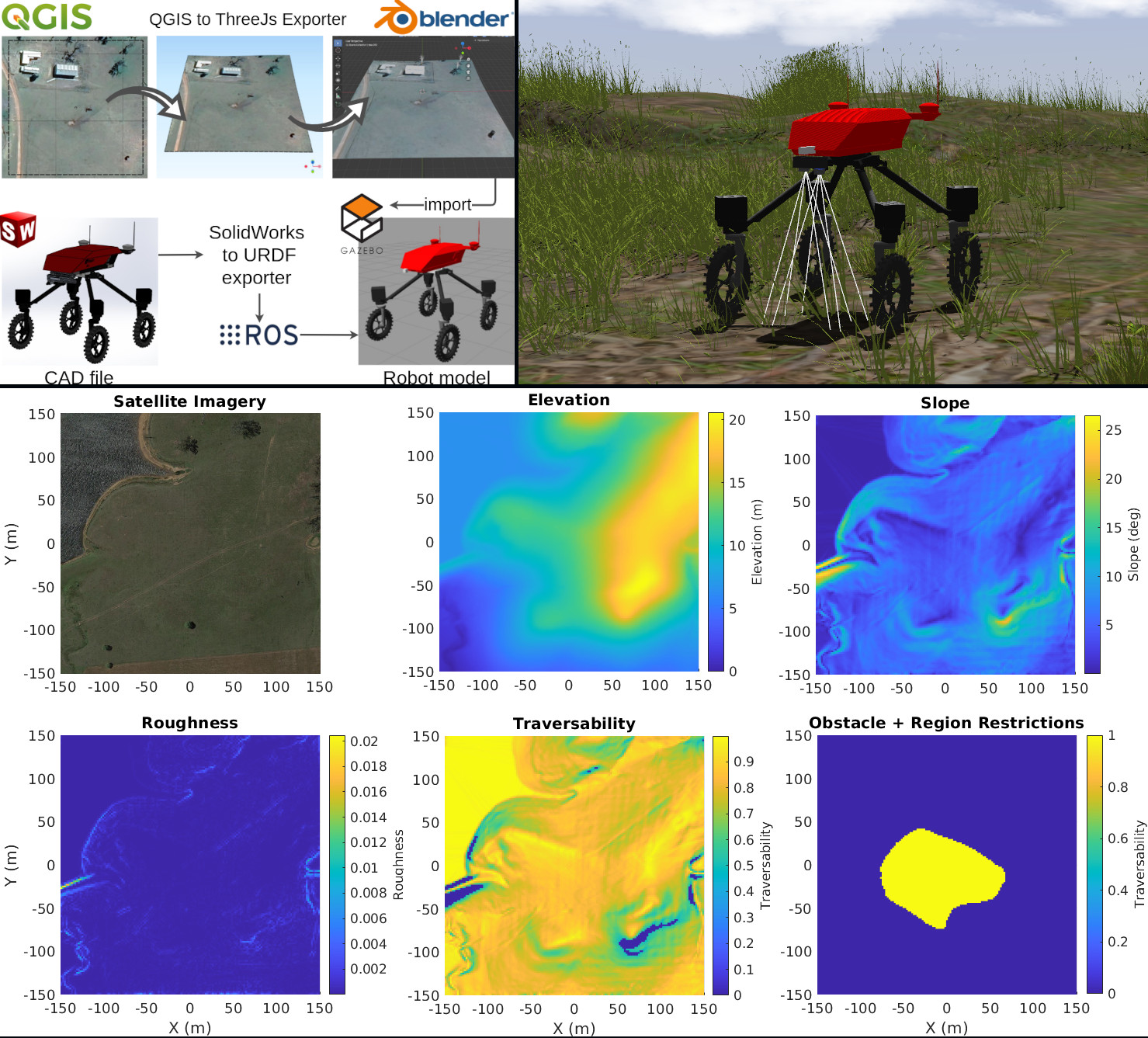

- Simulator/Digital-twin development — Developing a simulation environment mirroring the capabilities of the platform, and the properties of the operating environment.

Digital Twin Pipeline

A key innovation was the simulation-to-deployment pipeline. I developed a comprehensive digital twin architecture that allowed:

- Seamless transition — Code developed in simulation could deploy to physical hardware with minimal modification

- Parallel development — Multiple researchers could develop and test algorithms simultaneously without competing for robot time

- Rapid iteration — New features could be validated in simulation before risking hardware in the field

Technical Architecture

The system was built on ROS with a modular architecture separating concerns:

- Hardware abstraction layer — Isolated hardware-specific code, enabling the same high-level logic to run on different robot configurations

- Behaviour trees — Flexible task execution framework allowing complex autonomous behaviours to be composed from simpler primitives

- Safety systems — Multi-level safety monitoring with graceful degradation when sensors failed or obstacles appeared

Impact & Legacy

This GNC system became the foundation for numerous projects at ACFR:

- Agricultural monitoring and pasture assessment

- Blast hole inspection for Rio Tinto

- Bushfire trail monitoring

- Lunar prospecting algorithm development

The capabilities developed were instrumental in securing ongoing research funding and enabled the team to respond quickly to new project opportunities. Rather than spending months on basic robot functionality, researchers could focus immediately on their specific research questions.